Introduction: A Region in Ruins, a Partnership That Answered

The summer of 2025 will forever be etched in the memories of Southern Californians. A series of unprecedented wildfires—fueled by record-breaking heatwaves and dry Santa Ana winds—ripped through Los Angeles County, leaving a landscape of charred remains in their wake. In Pacific Palisades alone, 1,200 homes were reduced to ash; in Eaton Canyon, 800 more. Infrastructure crumbled: power lines melted, water mains burst, and community centers that had served as hubs for generations were gone. For the 15,000+ families displaced, the future looked grim. Traditional construction, already strained by labor shortages and supply chain delays, offered little hope—estimates suggested rebuilding would take 5–7 years, with costs soaring to $1.2 million per home, far beyond what insurance or savings could cover.

Then came a lifeline: a collaboration between ABB Robotics, a global leader in automation, and Cosmic Buildings, a trailblazing construction tech firm. Their pitch? AI-powered mobile robotic microfactories that could build homes 70% faster, 30% cheaper, and safer than conventional methods—right on the charred lots where families once lived. Six months later, the first of these homes is set to welcome its owners. This is the story of how robotics and AI are not just rebuilding houses, but redefining what’s possible in disaster recovery.

The Tech Behind the Miracle: How Robots and AI Build a Home in 12 Weeks

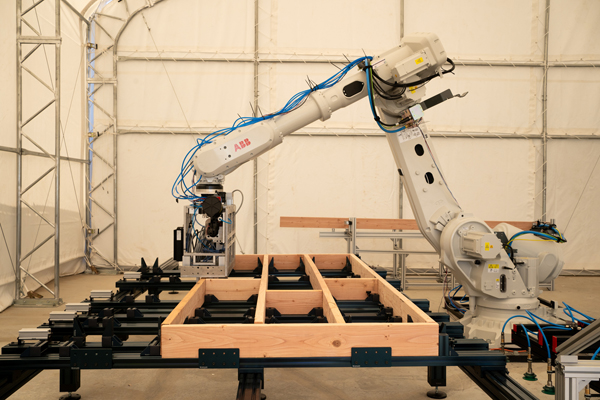

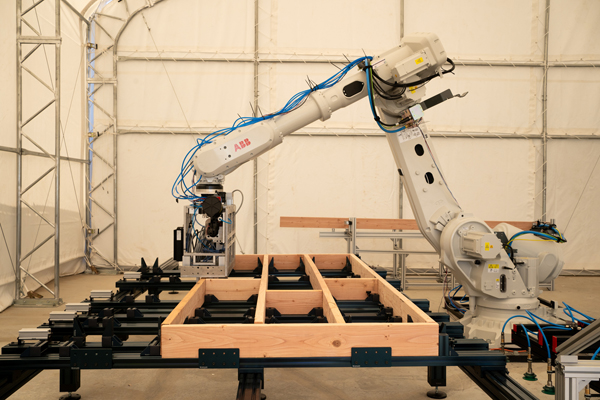

To understand the revolution, step inside Cosmic Buildings’ mobile microfactory parked on a lot in Pacific Palisades. Housed in a 40-foot shipping container retrofitted with climate control and safety systems, it’s a hive of precision engineering. At its heart: ABB’s IRB 6710 robot, a 6-axis industrial arm with a reach of 2.8 meters and repeatability of ±0.05 millimeters—meaning it can place a screw with the accuracy of a neurosurgeon.

“The IRB 6710 isn’t just a machine; it’s a collaborator,” says Elena Márquez, ABB’s lead robotics engineer on the project. “We’ve programmed it to handle everything from cutting structural panels to installing insulation, all while communicating with our digital twin software.” That software—ABB’s RobotStudio®—is where the magic begins. Before a single tool touches material, the entire build is simulated in 3D: the robot’s movements, material flow, even weather delays are modeled. “We can test 50 different construction sequences in a day,” Márquez explains. “If a panel is too heavy for the robot to lift in high winds? We adjust the schedule. If a supply delivery is late? The digital twin reoptimizes the workflow. It’s like having a crystal ball for construction.”

Cosmic’s AI system, meanwhile, acts as the “brain” of the operation. Its Building Information Model (BIM)“Our AI doesn’t just follow orders—it adapts,” says Dr. Priya Patel, Cosmic’s head of AI research. “Last month, we had a sudden rainstorm. The system detected moisture levels in the lumber, paused fabrication, and redirected the robot to seal the storage area—all in 12 seconds. A human crew might have missed that, leading to mold issues later.”

The result? A home that goes from design to move-in in 12 weeks. Here’s the breakdown:

Weeks 1–2: The family works with Cosmic’s design team to customize their home (layout, energy features, finishes) via a user-friendly app. Cosmic’s AI automatically checks the design against LA’s building codes, flagging issues (e.g., a window placement that violates wildfire safety) in real time.

Weeks 3–4: ABB’s RobotStudio® simulates the build, optimizing robot paths and material usage. The microfactory is transported to the lot, and the robot begins fabricating wall panels from fire-resistant cross-laminated timber (CLT), a material that’s 50% lighter than concrete but twice as strong.

Weeks 5–8: The robot assembles the panels onsite, with Cosmic’s AI monitoring alignment (to within 2 millimeters) and quality. Solar panels and battery systems—pre-fabricated offsite—are installed by a small human crew, guided by the AI’s step-by-step instructions.

Weeks 9–12: Finishing touches (painting, flooring, fixtures) are added. The AI runs a final inspection, using computer vision to check for cracks, misalignments, or safety hazards. A city inspector, equipped with a digital copy of the AI’s report, signs off in half the usual time.

For Families: More Than a Home—A Fresh Start

For the López family, the difference is visceral. Their 1960s Pacific Palisades home burned to the ground in the July 2025 fires. “We lived in a motel for 3 months, then with my sister’s family—6 of us in a 2-bedroom apartment,” says Carlos López, a high school teacher. “Our insurance paid out $600,000, but traditional builders quoted us $950,000 for a new home. We thought we’d have to leave the neighborhood we’d lived in for 20 years.”

Then they heard about Cosmic and ABB. Their new 1,800-square-foot home—with 3 bedrooms, a solar-powered HVAC system, and a roof designed to repel embers—cost $1.02 million, with Cosmic’s 30% cost reduction bringing it within their budget. “The best part? We watched it go up,” López says. “Every weekend, we’d visit the lot. The robot worked rain or shine, and the crew explained every step. My kids called it ‘our metal builder friend.’”

Their home, like all others in the project, includes features tailored to Southern California’s risks: greywater recycling systems that capture shower and sink water for landscaping (critical in droughts), battery backups that keep the lights on during wildfire-related power outages, and walls coated in intumescent paint that swells to form a fire-resistant barrier when heated. “We don’t just feel safe—we feel prepared,” López adds.

The Numbers: Why This Isn’t Just a “Cool Tech” Gimmick

Critics initially dismissed the project as a publicity stunt, but the data tells a different story. Compared to traditional builds in the area:

Time: 12 weeks vs. 6–9 months. This slashes temporary housing costs by $15,000–$30,000 per family.

Cost: $550–$700 per square foot vs. $800–$1,000+. For a 2,000-square-foot home, that’s savings of $200,000–$600,000.

Waste: 5% material waste vs. 25–30% in traditional construction. In a region where landfills are overflowing, this has kept 12 tons of debris out of dumps so far.

Safety: 0 workplace injuries reported vs. the national average of 3.2 injuries per 100 construction workers. “Robots handle the heavy lifting—literally,” says Jimenez, Cosmic’s site supervisor. “No one’s lifting 80-pound drywall sheets in 100-degree heat. That’s a game-changer for worker safety.”

The Future: Scaling Beyond LA

The partnership isn’t stopping at 100 homes by 2027. ABB and Cosmic are already planning to deploy 5 more microfactories in California—targeting areas hit by the 2024 Oakland wildfires and 2025 San Diego floods. “We’re learning from every build,” says Sasha Jokic, Cosmic’s CEO. “Our next microfactory will include a 3D printer for custom fixtures, and we’re integrating ABB’s autonomous mobile robots to transport materials across the site—no human drivers needed.”

For ABB, the project is a proof of concept for robotics in construction, a $1.3 trillion global industry long resistant to automation. “Construction is one of the last frontiers for robotics, and for good reason—it’s messy, variable, and site-specific,” says Marc Segura, ABB Robotics’ president. “But by pairing our robots with Cosmic’s AI, we’re showing that automation can thrive here. We’re already in talks with builders in Texas and Florida, where hurricanes demand fast, resilient rebuilding.”

Conclusion: A New Playbook for Disaster Recovery

As the López family prepares to move in next month, Carlos López reflects on what the project means for his community. “When the fire happened, we felt powerless. Now? We’re watching homes rise from the ashes faster than anyone thought possible. It’s not just about the robot—it’s about hope. This technology isn’t replacing people; it’s giving us the tools to rebuild our lives.”

In a world where climate disasters are becoming more frequent, the ABB-Cosmic partnership offers a blueprint: innovation that’s not just smart, but compassionate—built to heal communities, one home at a time.

——

Xingruijia focuses on providing ABB industrial automation full range product services and your intelligent control solution partner

If you would like to learn more about our products and services, please feel free to contact us at any time!

Sales Manager : Jinny

Email : sales1@xrjdcs.com

Whatsapp/Mobile:+86 15359273791