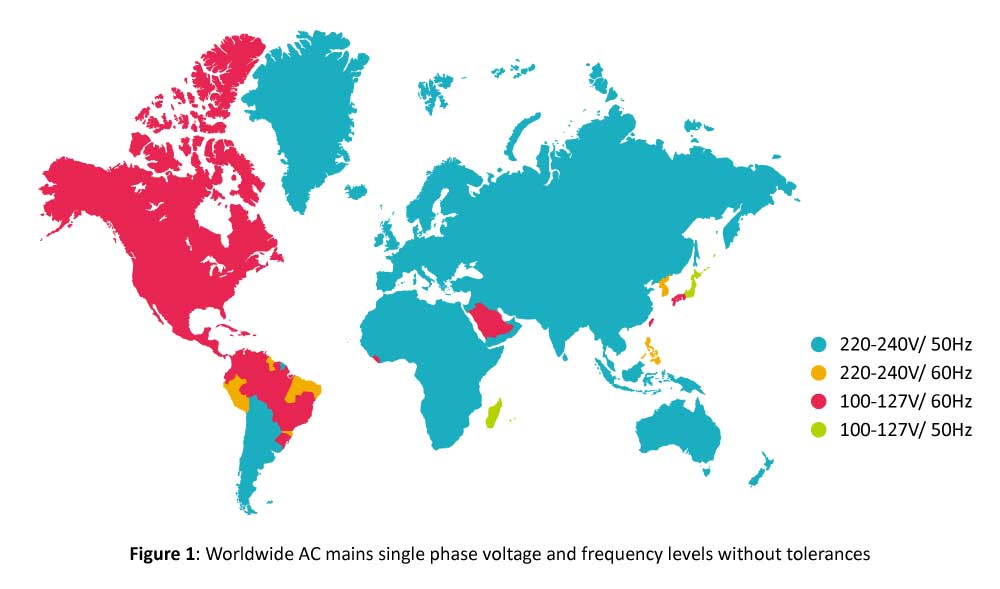

The global AC power supply voltage range is 85Vac to 264Vac, and many power supplies today can operate within this entire range.

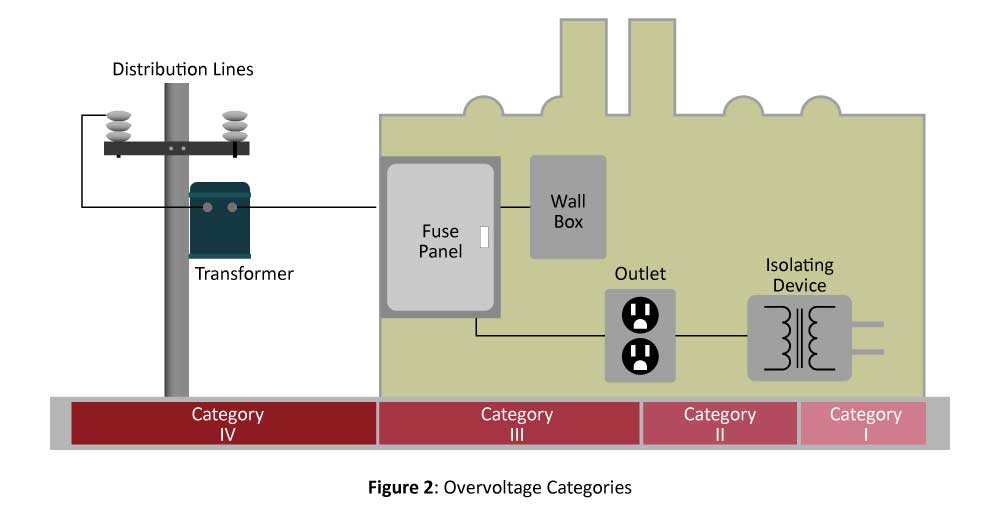

Another challenge in energy applications comes from the fact that devices such as chargers or wall boxes are directly connected to the fuse panel. This means that they are more susceptible to grid transients than devices connected to sockets through cables and plugs, and therefore must comply with overvoltage category III (OCV III) with 4kVac isolation (Figure 2). This also applies to auxiliary power sources used in chargers or wall boxes.

Another challenge in energy applications comes from the fact that devices such as chargers or wall boxes are directly connected to the fuse panel. This means that they are more susceptible to grid transients than devices connected to sockets through cables and plugs, and therefore must comply with overvoltage category III (OCV III) with 4kVac isolation (Figure 2). This also applies to auxiliary power sources used in chargers or wall boxes.

These systems must also be able to tolerate faults in power wiring or neutral lines. Unintended phase connections during installation, or open circuits in the neutral line (even nearby), can cause system imbalance and result in higher voltage. Therefore, the input voltage of the power supply will be monitored in order to disconnect expensive high-power blocks in the event of such faults.

The monitoring circuit must be able to operate in all situations, so P-Duke offers a range of small AC/DC converters that not only comply with OVC III standards, but can also operate within a wide voltage range of 85 to 530Vac. Even if a phase is incorrectly connected to the neutral line, the auxiliary power supply and monitoring circuit will still operate and protect the power level.

Modern systems should be ready for integration into smart grids or smart home environments. This allows the control system to match the actual availability of electricity in the grid. When there is surplus energy, the car battery can be charged and act as an energy buffer to stabilize the power grid. High energy consuming household appliances will only be turned on when there is sufficient energy available.

The monitoring circuit must be able to operate in all situations, so P-Duke offers a range of small AC/DC converters that not only comply with OVC III standards, but can also operate within a wide voltage range of 85 to 530Vac. Even if a phase is incorrectly connected to the neutral line, the auxiliary power supply and monitoring circuit will still operate and protect the power level.

Modern systems should be ready for integration into smart grids or smart home environments. This allows the control system to match the actual availability of electricity in the grid. When there is surplus energy, the car battery can be charged and act as an energy buffer to stabilize the power grid. High energy consuming household appliances will only be turned on when there is sufficient energy available.

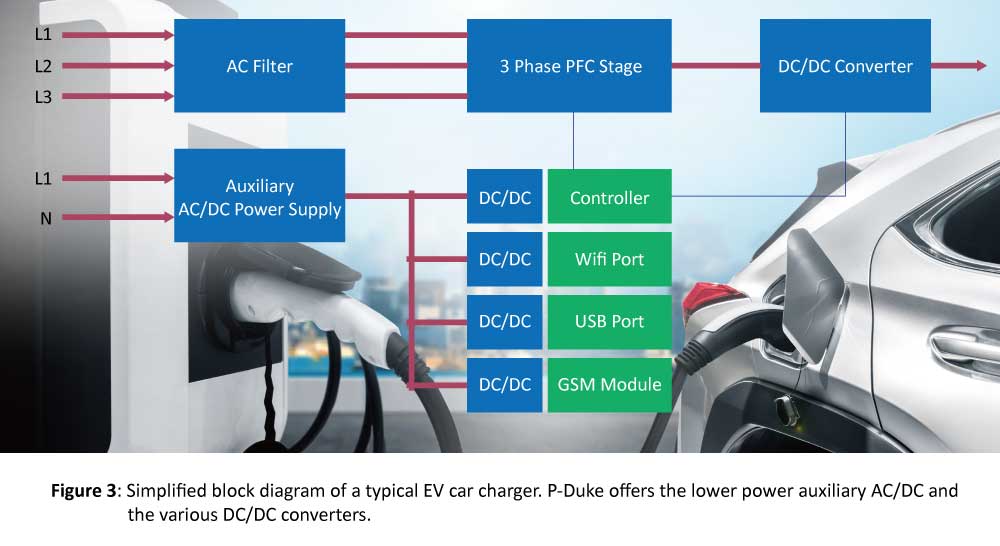

This means that more phases are needed to communicate with the power grid or smart home controllers. The power supply voltage range for interphase, display, touchpad, or relay is 3.3V to 24V, and can be generated from the auxiliary power supply voltage bus through a small isolated or non isolated converter (Figure 3).

As mentioned at the beginning of the article, due to the non constancy of energy flow, the integration of renewable energy also requires expanding storage options. Nowadays, hydroelectric power plants are used for this purpose, pumping water back into reservoirs when there is excess energy. However, their capacity is limited, and the most obvious way to store energy is through the use of batteries.

Lead acid batteries have been in use for decades, but they are heavy, have relatively low energy density, and have a slow charging process, with only about 300-600 charges.

Compared to lead-acid batteries, lithium batteries have several advantages. For example, they are not only lighter and smaller than lead-acid batteries, but also charge faster, reaching thousands of charging cycles. This makes them very suitable for use in mobile devices and electric vehicles.

Compared to lead-acid batteries, lithium batteries have several advantages. For example, they are not only lighter and smaller than lead-acid batteries, but also charge faster, reaching thousands of charging cycles. This makes them very suitable for use in mobile devices and electric vehicles.

But the availability of the materials they need is limited, and some of them were obtained under problematic conditions. A typical electric vehicle battery requires not only 120-180 grams of lithium per kilowatt hour of capacity, but also some other materials with limited availability. According to research by the German automotive club ADAC, a 50kWh battery for a car contains approximately 4 kilograms of lithium, 11 kilograms of manganese, 12 kilograms of cobalt, 12 kilograms of nickel, and 33 kilograms of graphite.

In order to shift mobility from internal combustion engines to electric drive, hundreds of thousands of tons of these materials will be needed in the future. The method of recycling this material is very complex, and according to experts, some methods are still in the development or testing stage. Therefore, people are looking for alternative solutions, not only in battery technology, but also in energy storage methods.

You may have heard of batteries based on aluminum sulfur, sodium ions, carbon copper, or iron oxygen. At present, it has not been launched for the mass market, as these are options that use a large amount of available materials and have fewer mining issues.

For non mobile applications, the size and weight of the battery are not as important. At the bottom of the wind turbine tower, even larger batteries have enough space. When there is excess energy in the power grid, the energy generated by turbines can be stored there and fed into the grid in case of energy shortage. Usually, energy only needs to be temporarily stored in the grid for 12 to 24 hours.

But each battery technology has different voltages, and if someone wants to design a future oriented system that is compatible with the different battery technologies and battery quantities used in applications, this is a real challenge. Therefore, power supply manufacturers such as P-Duke offer converters with an input voltage range of 2:1 to 12:1. Through these converters, many different battery technologies can be covered.

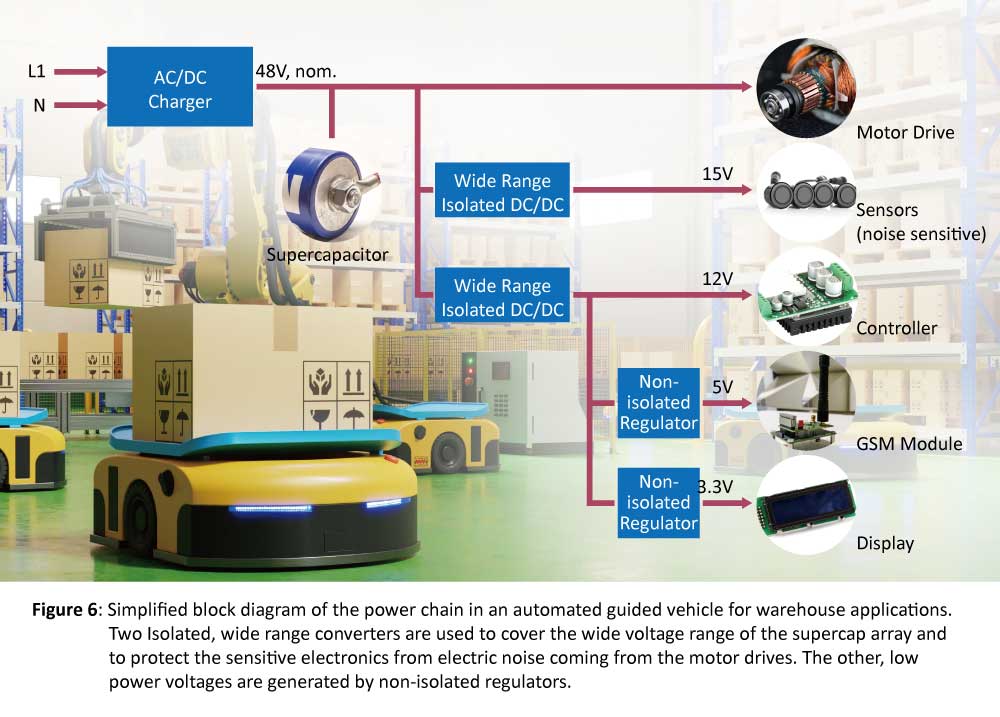

Supercapacitors are an interesting alternative to batteries because they have a longer lifespan, up to one million charging cycles, and very high charging currents. Unlike batteries, supercapacitors are not damaged by deep discharge. They are very suitable for applications that require less than 1-2 minutes of electricity but have a large number of charging cycles. Why not use supercapacitors on the transportation robots in the warehouse, as they can only travel short distances and can be charged in a few seconds. Unlike batteries, the output voltage of supercapacitors largely depends on their charging status. Due to the need for stable voltage in most electronic loads, a DC/DC converter with a very wide input range is required.

There are many other ways to store energy. Hydrogen can be obtained from the air through electrolysis. In further process steps, methane, the main component of natural gas, can be produced. Both gases can be stored, transported, and used as fuel, such as in fuel cells, which is another emerging technology. Nowadays, even drones are using fuel cells.

Other methods of storing mechanical energy for future use are pneumatic and flywheel storage devices. More than 15 years ago, a startup company in the United States hoped to use compressed air for wind turbines, but it was never realized due to the solution being too complex and inefficient. But there are still some projects dedicated to storing excess energy generated by wind turbines

Other methods of storing mechanical energy for future use are pneumatic and flywheel storage devices. More than 15 years ago, a startup company in the United States hoped to use compressed air for wind turbines, but it was never realized due to the solution being too complex and inefficient. But there are still some projects dedicated to storing excess energy generated by wind turbines

in compressed air.

In 1950, the first batch of gyro buses were launched, which could recover braking energy, but required a charging station every 4-6 kilometers, which was not suitable for modern public transportation. Nowadays, flywheel storage devices are mainly used to provide high power for a short period of time, such as stabilizing the power grid.

These are just a few examples; The energy market is complex with thousands of options, and new ideas and technologies emerge almost every day, each with different requirements for the required power sources. In addition, in order to achieve energy conservation and widespread use, modern systems must communicate with each other. All of these systems require a regulated power supply voltage to be generated from various sources.

In 1950, the first batch of gyro buses were launched, which could recover braking energy, but required a charging station every 4-6 kilometers, which was not suitable for modern public transportation. Nowadays, flywheel storage devices are mainly used to provide high power for a short period of time, such as stabilizing the power grid.

These are just a few examples; The energy market is complex with thousands of options, and new ideas and technologies emerge almost every day, each with different requirements for the required power sources. In addition, in order to achieve energy conservation and widespread use, modern systems must communicate with each other. All of these systems require a regulated power supply voltage to be generated from various sources.

The voltage level and transient specifications of the AC power grid have been established for many years, and companies such as P-DUKE provide various AC/DC power solutions that meet various requirements (Figure 4, P-DUKE’s AC/DC solutions)

For DC power supplies, the situation is even more complex as the new system is expected to enter the market. But there is already a solution today. Different battery voltages have been used for decades in the telecommunications and railway markets. System manufacturers in these markets hope to provide a solution, so the converter series designed by power manufacturers such as P-DUKE even covers an extremely wide input range of 16V to 160V in railway applications, and achieves power levels of up to 200W. The standard output voltage range of these converters is 5V to 53V, which can be used for various battery voltages in all types of energy market applications.

LAN, WLAN, GSM, and other communication modules, security and monitoring devices, displays, touch panels, or relays all require a regulated power supply voltage, whether or not isolated from internal control circuits. With a wide range of converters, designers should be able to easily find ready to use solutions. (Figure 6)

All of these converter modules are easy to deploy, providing a plug and play solution not only during design time but also when system input, output, or power specifications change later. This makes every design future oriented and prepared for emerging markets, which have many new opportunities but also many unknowns.

Leave a comment

Your email address will not be published. Required fields are marked *