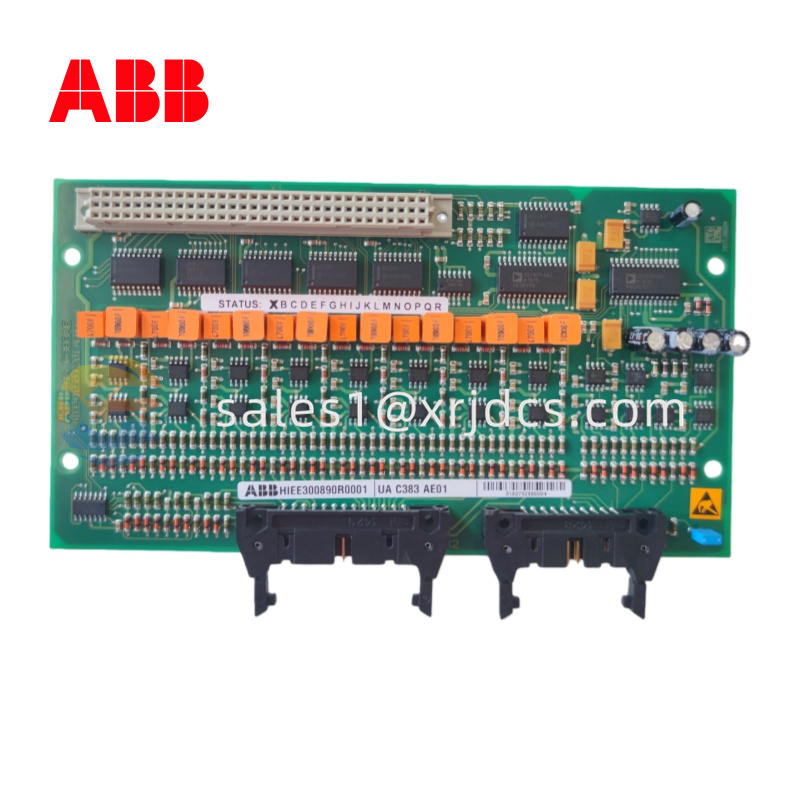

ABB 3BHE051592R0101

ABB 3BHE051592R0101 is a high-performance process controller module under the ABB AC 800M Series, specifically designed for industrial automation and process control systems. It is applicable to critical industries such as power, petrochemicals, and water treatment. As a core component of the AC 800M Controller, this module is responsible for executing complex control logic, data acquisition, and communication management, ensuring the stability, safety, and efficiency of production processes.

The core values of 3BHE051592R0101 are as follows:

High-performance processing: Equipped with a multi-core processor architecture, supporting multi-task real-time control.

Multi-function integration: Seamlessly integrating I/O modules, communication networks, and upper-level systems.

High reliability: Featuring redundant design and hot-swap support to ensure continuous system operation.

Product Parameters

Product Model: 3BHE051592R0101

Manufacturer: ABB

Product Type: Process Controller Module

Compatible System: ABB AC 800M Control System

Processor: Multi-core ARM Cortex-A9

Memory: 1GB RAM / 4GB Flash (expandable)

Communication Interfaces: 2× Ethernet (Gigabit), 1× RS-485, 1× USB

Supported Protocols: OPC UA, Modbus TCP, Profibus DP, IEC 61850

Operating Temperature Range: -20°C to +60°C (-4°F to +140°F)

Protection Class: IP20 (must be installed in a control cabinet)

Installation Method: DIN Rail or rack mounting

Power Supply Voltage: 24V DC (±10%)

Power Consumption: ≤15W

Certification Standards: CE, UL, IEC 61131-2

Structure and Composition

3BHE051592R0101 adopts a modular industrial design, with main components including:

Core Processing Unit:

Multi-core processor (e.g., ARM Cortex-A9) running a Real-Time Operating System (RTOS), ensuring low latency (≤1ms) for control tasks.

Communication Interface Board:

Dual Gigabit Ethernet ports (supporting redundant ring networks), RS-485 (for Modbus RTU), and USB (for program downloading).

Backplane Bus Interface:

High-speed parallel bus, expandable to S800 I/O modules (e.g., SD822 digital module).

Power Management Module:

Wide voltage input (24V DC), with built-in reverse connection protection and surge suppression.

Status Indicators:

LEDs displaying power, communication, operation status, and fault codes (e.g., CPU overload).

Metal Enclosure:

Made of aluminum alloy, providing EMI shielding and heat dissipation functions.

Key Features and Advantages

High-performance real-time control:

Control cycle of ≤1ms, suitable for high-speed process control (e.g., PID regulation, sequential control).

Supports multi-task scheduling, enabling simultaneous operation of logic control, data logging, and communication tasks.

Openness and compatibility:

Natively supports the Control Builder M development environment, compatible with IEC 61131-3 programming languages (LD, FBD, ST).

Integrates with third-party SCADA/MES systems (e.g., Ignition, Siemens WinCC) via OPC UA.

Industrial-grade reliability:

Wide operating temperature range from -20°C to +60°C, with vibration resistance of 5g @ 100Hz.

Watchdog timer and fault self-diagnosis function to ensure long-term stable operation of the system.

Flexible expandability:

Connects up to 64 I/O modules (e.g., analog input AI823) via the backplane.

Optional dedicated communication modules (e.g., CI854 Profibus DP) for multi-protocol integration.

Application Fields

3BHE051592R0101 is suitable for the following scenarios:

Process industry:

PID temperature/pressure control of chemical reactors.

Flow regulation and safety interlocking of oil pipeline pumping stations.

Power industry:

Speed control and protection of gas turbines/steam turbines.

Water treatment:

Pump group linkage and water quality monitoring control.

Typical Application Case:

In chemical plants, 3BHE051592R0101 connects field instruments via Profibus DP, executes closed-loop temperature control of reactors, and uploads data to the SCADA system through OPC UA.

Related Products

AI823: Analog input module, expanding signal acquisition capabilities.

SD822: Digital input module, used for switch status monitoring.

CI854: Profibus DP communication module, expanding network interfaces.

Control Builder M: ABB engineering software, used for module configuration and programming.

Installation and Maintenance

Installation Key Points

Fix the module using DIN Rail or screws, ensuring a heat dissipation space of ≥50mm.

A 24V DC power supply must be equipped with a fuse (2A recommended).

Use CAT6 shielded cables for Ethernet to avoid communication interference.

Maintenance Recommendations

Regularly back up programs to USB or network storage.

Monitor CPU load rate via software (long-term load <80% recommended).

Check the status of cooling fans (if equipped) every 2 years and clean dust.

Xingruijia focuses on providing ABB industrial automation full range product services and your intelligent control solution partner

If you would like to learn more about our products and services, please feel free to contact us at any time!

Sales Manager : Jinny

Email : sales1@xrjdcs.com

Whatsapp/Mobile:+86 15359273791

Switzerland

Switzerland

.jpg)

.jpg)

.jpg)