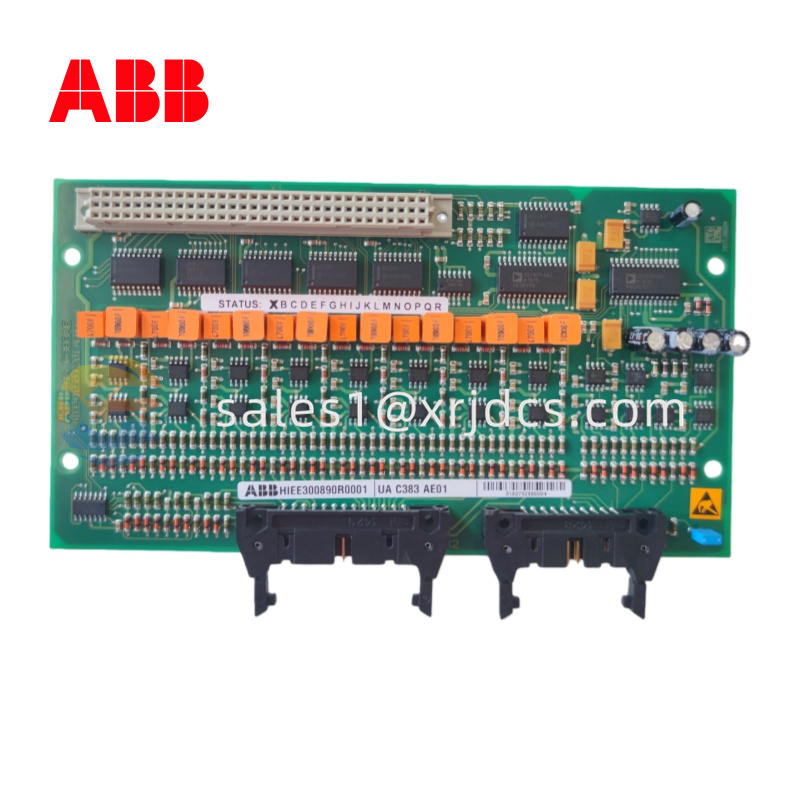

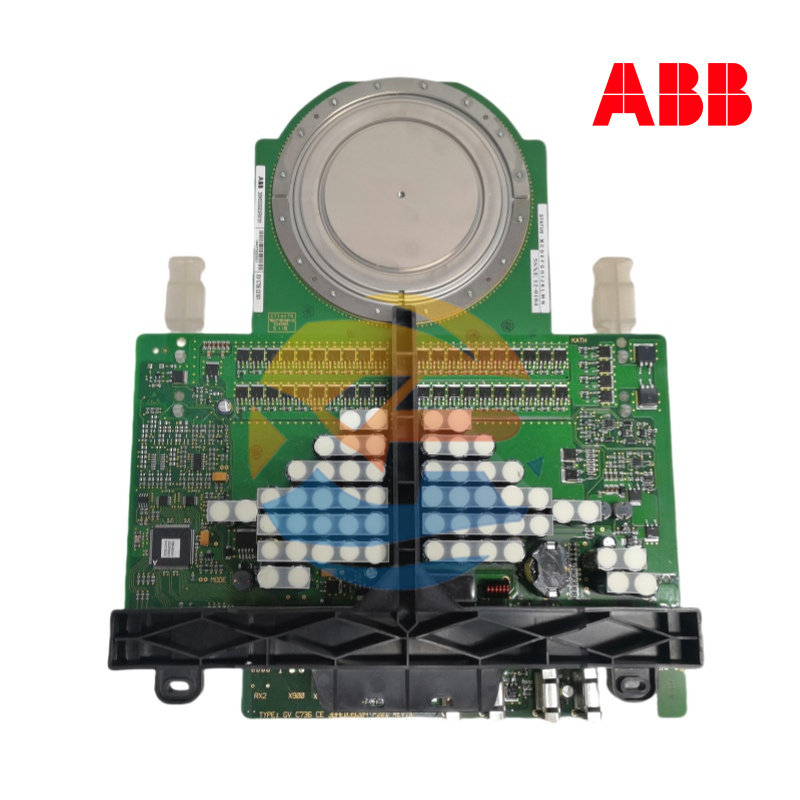

ABB 3BHB030310R0001 5SHY4045L0006

ABB 3BHB030310R0001 5SHY4045L0006 is a high-voltage inverter power unit module under the ABB ACS 8000 series, specifically designed for large-scale industrial drives and energy management systems. It is suitable for high-voltage motor speed control in industries such as mining, metallurgy, cement, and power generation. As a core power component of multilevel inverters, this module adopts IGBT technology to achieve efficient energy conversion, supporting motor soft start, speed regulation, and energy-saving control to ensure stable equipment operation and reduce energy consumption.

Core Values of 5SHY4045L0006

Efficient Energy Conversion: Adopts advanced IGBT topology, with an efficiency of over 98.5%.

Modular Redundant Design: Supports N+1 redundancy configuration to improve system availability.

Intelligent Fault Protection: Real-time monitors temperature, voltage, and current, providing multi-layer protection.

Product Specifications

Product Model: 3BHB030310R0001 5SHY4045L0006

Manufacturer: ABB

Product Type: High-Voltage Inverter Power Unit Module

Rated Voltage: 3300V AC (input/output)

Rated Current: 450A (continuous) / 500A (1-minute overload)

Switching Frequency: ≤500Hz (for IGBT)

Cooling Method: Forced air cooling (built-in fan)

Protection Class: IP00 (must be installed in an inverter cabinet)

Operating Temperature Range: 0°C to +50°C (32°F to +122°F)

Communication Interface: Fiber optic interface (for connection to the main controller)

Fault Protection: Overcurrent, overvoltage, overheating, short circuit

Certification Standards: UL, CE, IEC 61800-4

Structure and Composition

5SHY4045L0006 adopts a modular design, with main components including:

IGBT Power Module: Features high-voltage IGBT chips (e.g., StakPak technology) for low switching losses.

Driver Circuit: Uses fiber optic isolated driving to ensure complete isolation between control signals and high-voltage components.

DC Bus Capacitors: Consists of electrolytic capacitor banks to smooth DC voltage and provide energy buffering.

Temperature Sensors: PT100 or NTC sensors for real-time monitoring of IGBT heatsink temperature.

Status Indicators: LED lights to display operating status and fault codes (e.g., overheating, overcurrent).

Fiber Optic Interface: Receives PWM control signals and uploads fault status to the main controller.

Key Features and Advantages

High-Performance Energy Conversion

The multilevel topology outputs voltage close to a sine wave, reducing motor harmonic losses (THD ≤ 5%).

Equipped with dynamic voltage regulation function to adapt to grid fluctuations (±10% of rated voltage).

High-Reliability Design

N+1 redundancy allows the system to continue operating at reduced capacity when a single module fails.

Thermal redundancy design with dual backups for key components (e.g., driver power supply).

Intelligent Monitoring and Diagnostics

Real-time collection of IGBT junction temperature (calculated via Vce saturation voltage drop) to warn of overheating risks.

Generates health reports and predicts maintenance cycles through the ACS 8000 Assist software.

Industrial-Grade Durability

Operates at full load under an ambient temperature of 50°C without derating.

Complies with the IEC 61800-4 high-voltage inverter standard.

Application Fields

5SHY4045L0006 is mainly used in the following scenarios:

Mining Industry: Inverter drive for mine hoists (e.g., ABB Hoist system).

Metallurgy Industry: Control of main drive motors for rolling mills.

Cement Industry: Speed regulation of high-voltage motors for raw material mills.

Energy Industry: Energy-saving transformation of large water pumps and fans.

Typical Application Case: In an iron ore hoisting system, 5SHY4045L0006 serves as the power unit of the ACS 8000 inverter to drive a 4000kW/6kV synchronous motor. It achieves precise speed control (±0.1%) and an energy-saving rate of 25%.

Related Products

3BHB030310R0002: Control unit module, used as a matching component.

5SHY3545L0006: 3000V/400A power unit, the low-power version.

ACS 8000 Assist: Diagnostic software for remote monitoring of module health status.

Installation and Maintenance

Installation Key Points

Use insulated tools for installation and ensure the busbar connection torque (usually 50-60 Nm).

Ensure the fiber optic bending radius is ≥50mm to avoid core breakage.

Maintenance Recommendations

Clean the air duct filter every six months (the cycle needs to be shortened in dusty environments).

Regularly measure the capacitor capacity (replace if the capacity drops by 20%).

Xingruijia focuses on providing ABB industrial automation full range product services and your intelligent control solution partner

If you would like to learn more about our products and services, please feel free to contact us at any time!

Sales Manager : Jinny

Email : sales1@xrjdcs.com

Whatsapp/Mobile:+86 15359273791

Switzerland

Switzerland

.jpg)

.jpg)

.jpg)

.jpg)