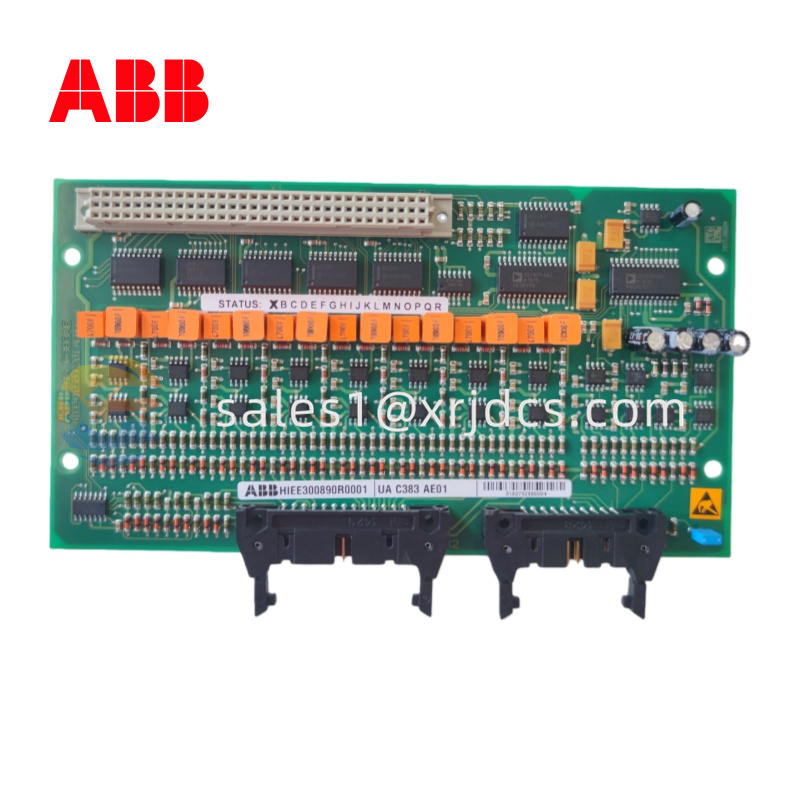

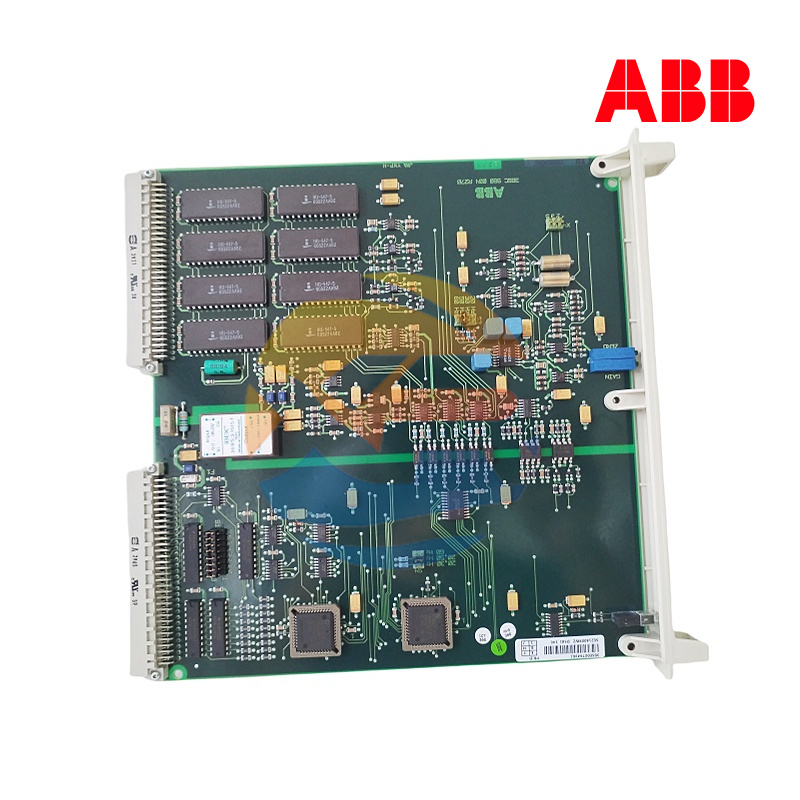

ABB DSAI146

The ABB DSAI146 is a high-precision and high-reliability analog input module, which is part of the well-known Advant OCS (Open Control System) series under ABB, specifically belonging to the DSBC series of distributed I/O units within the MasterPiece 200/200L family. In automated systems, this module plays a key role as the "sensory nerve ending" – it is specially designed to receive various analog sensor signals from the field, convert them into high-precision digital signals, and send these signals to upper-level controllers (such as ABB MasterPiece series PLCs) for processing and logical operations. The core value of the ABB DSAI146 lies in its excellent signal processing capability, extremely high channel isolation, and strong anti-interference performance. It can ensure the collection of accurate and stable process data (such as temperature, pressure, flow rate, and liquid level) even in harsh industrial environments filled with noise and potential differences. This lays a solid data foundation for achieving precise process control and equipment monitoring, making it a crucial cornerstone for building high-reliability DCS and PLC systems.

Product Specifications

- Product Model: DSAI146

- Manufacturer: ABB

- Product Type: Analog Input Module (for Advant OCS DSBC Station)

- Number of Channels: 16 channels (single-ended)

- Input Signal Type: Voltage input: 0-10 VDC, ±10 VDC; Current input: 0-20 mA, 4-20 mA (250Ω resistor in parallel required)

- Resolution: 16 bits (including sign bit)

- Accuracy (Typical Value): ±0.1% of full scale (under rated conditions)

- Conversion Time: < 1 ms per channel

- Isolation Between Channels: None (all channels share a common ground)

- Input Filter: Software-configurable

- Common Mode Rejection Ratio (CMRR): > 100 dB

- Operating Temperature: 0°C to +60°C

- Installation Method: Modular, inserted into the backplane of the DSBC distributed I/O station

Structure and Composition

The ABB DSAI146 adopts a compact Eurocard standard modular design. Its green PCB board is vertically inserted into the corresponding slot of the DSBC station backplane through a multi-pin connector at the rear. The front of the module is equipped with a row of channel status indicator lights, which are used for quickly diagnosing the working status of each channel. The core of its internal structure is a high-performance 16-bit analog-to-digital converter (ADC), which scans 16 input channels sequentially through a multiplexer (Multiplexer). Each channel is equipped with a precision signal conditioning circuit, including a precision sampling resistor network for current measurement and an attenuation and buffer circuit for voltage measurement. It should be noted that the 16 channels of this module adopt a non-isolated design and share a common reference ground (COM). This means it is more suitable for application scenarios where all sensor signals share a common ground and there is no earth loop interference. The address and configuration of the module are set through the DIP switches on the backplane or the upper computer software.

Key Features and Advantages

High Precision and High Resolution

With its 16-bit ADC and precision circuit design, the ABB DSAI146 can provide a measurement accuracy of up to ±0.1%, which is sufficient to meet the strict monitoring and control requirements of most process industries. Its high resolution ensures that even small changes in signals are captured clearly and accurately, making high-precision control loops possible.

Flexible Input Configuration and Fast Response

This module supports two of the most common analog signal types: voltage and current. Users only need to change the wiring method (a precision resistor in parallel is required for current signals) to switch between the two types, providing good adaptability. The conversion speed of less than 1 millisecond per channel ensures that the system can quickly respond to changes in on-site processes, meeting the needs of real-time control.

Powerful System Integration and Reliability

As a member of the Advant OCS system, the DSAI146 achieves seamless integration with ABB MasterPiece series controllers and can exchange data through the high-efficiency MB300 bus. Its industrial-grade design and manufacturing standards ensure long-term stable operation in a wide temperature range and complex electromagnetic environments, with an extremely high Mean Time Between Failures (MTBF), maintaining the high availability of the entire control system.

Application Fields

The ABB DSAI146 is classic and reliable, and is widely used in various continuous and batch process industries covered by the ABB Advant OCS system. In the chemical industry, it is used to connect pressure transmitters, level gauges, and flowmeters to monitor the status of reaction kettles and pipelines. In the pharmaceutical field, it collects key process parameters such as temperature and pH value to ensure that production complies with strict quality standards. In power plants and water treatment plants, it is used to monitor pump vibration, water turbidity, and chemical additive dosage. In addition, in many scenarios that require a large number of analog signal collections, such as papermaking, metallurgy, and food processing, the DSAI146 is a trustworthy choice, solving the core need of converting continuous physical quantities into reliable digital data.

Installation and Maintenance

Pre-Installation Preparation

Before installing the ABB DSAI146, it is necessary to ensure that the power supply of the entire DSBC station is completely turned off. Confirm that the module model is compatible with the backplane slot. Plan the wiring method according to the sensor type (voltage or current), and prepare a 250Ω precision parallel resistor for current signals. Carefully check whether the shielding layer of the on-site signal cable is intact and grounded at one end to avoid interference.

Maintenance Recommendations

Daily maintenance mainly includes regularly checking whether the status of the module indicator lights is normal. Periodically use a standard signal source (such as a calibrator with higher precision) to verify the accuracy of key channels, ensuring that the measured values are within the allowable error range. If there is drift or abnormality in the measured values, first check the on-site sensors, terminal blocks, and grounding conditions – because the non-isolated common ground design is relatively sensitive to common-mode interference on the line. When cleaning, use an anti-static brush to remove dust from the module and backplane slots.

Xingruijia focuses on providing ABB industrial automation full range product services and your intelligent control solution partner

If you would like to learn more about our products and services, please feel free to contact us at any time!

Sales Manager : Jinny

Email : sales1@xrjdcs.com

Whatsapp/Mobile:+86 15359273791

Switzerland

Switzerland

.jpg)

.jpg)

.jpg)