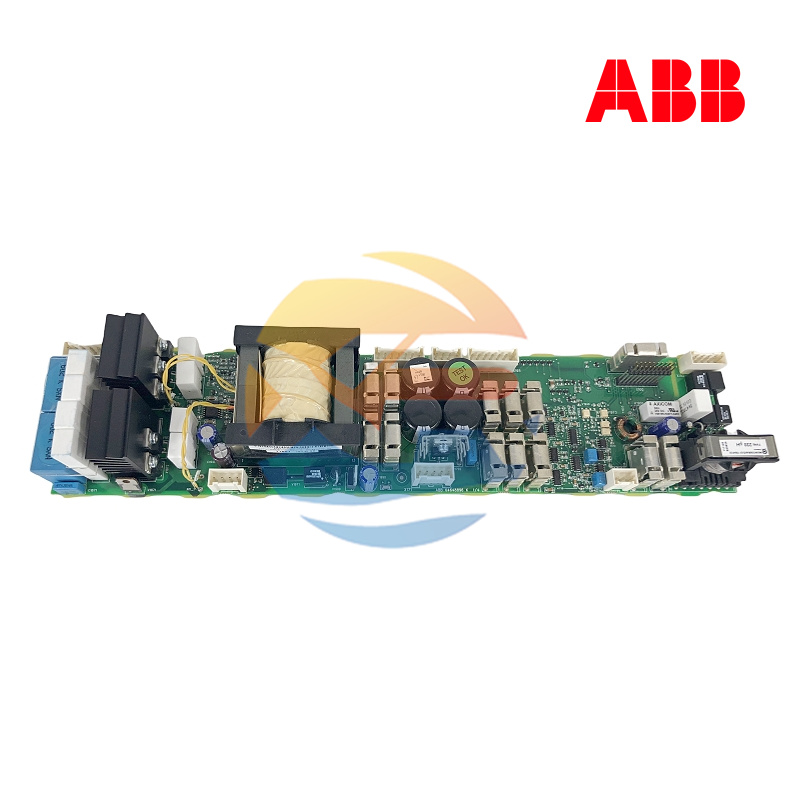

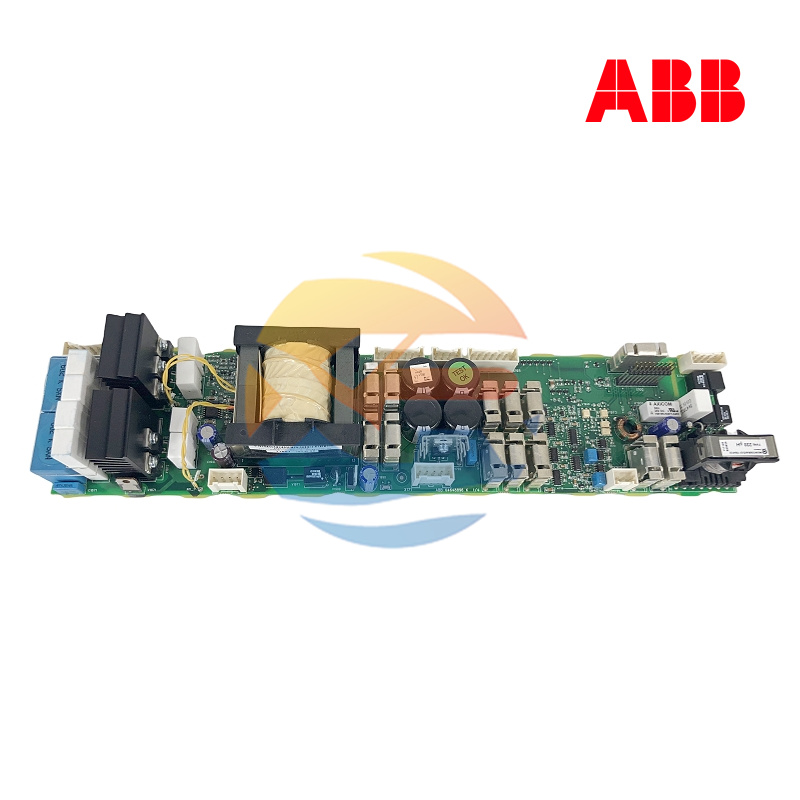

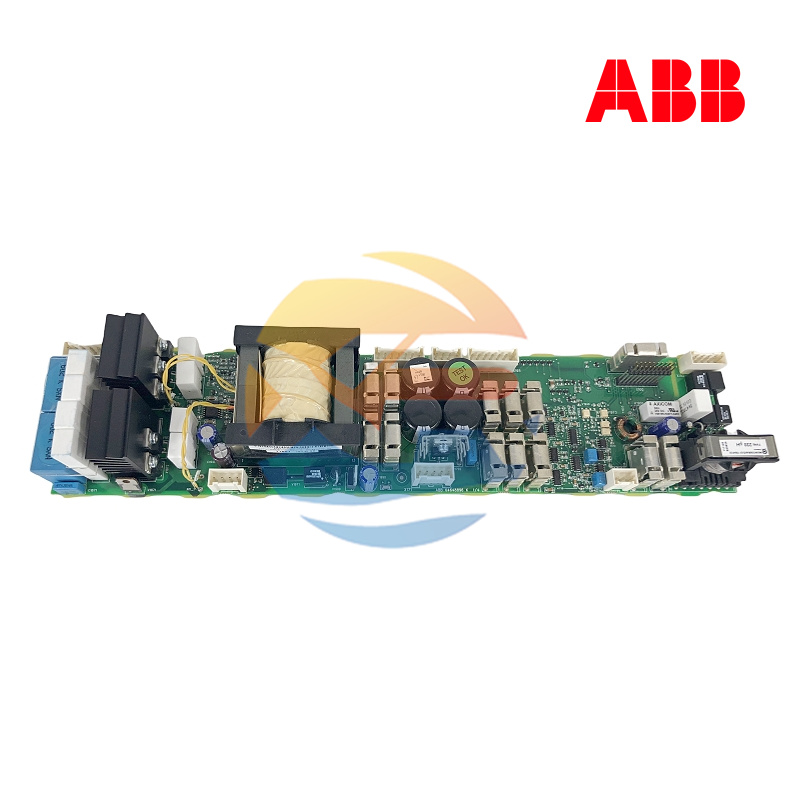

ABB DSMB-01C

The ABB DSMB-01C is a high-performance digital servo module designed by the ABB Group for its classic S800 I/O series. This module plays a key role as the "core of precise motion control" in the ABB automation system. It is specifically used in conjunction with ABB's servo drives and motors to achieve high-precision control of position, speed, and torque.

Equipped with advanced control algorithms and real-time communication technology, the ABB DSMB-01C module can process high-frequency feedback signals from encoders and output precise control commands. This ensures that the servo system responds quickly and accurately to the motion commands from the controller.

Product Parameters

Product Model: DSMB-01C

Manufacturer: ABB

Product Type: Digital Servo Module

Applicable Series: S800 I/O Series

Control Channels: 1 servo channel

Feedback Interface: Incremental encoder interface (A/B/Z signals)

Output Signal: ±10V analog output (for servo drive control)

Resolution: 24-bit high-resolution encoder processing

Control Cycle: ≤250μs (high-speed real-time control)

Position Accuracy: ±1 pulse (high-precision positioning)

Speed Range: 0-3000rpm (configurable)

Interface Type: Front-end fiber optic interface (for communication with the controller)

Operating Temperature: 0°C to +55°C

Storage Temperature: -25°C to +70°C

Protection Class: IP20

Installation Method: S800 Rail Mounting

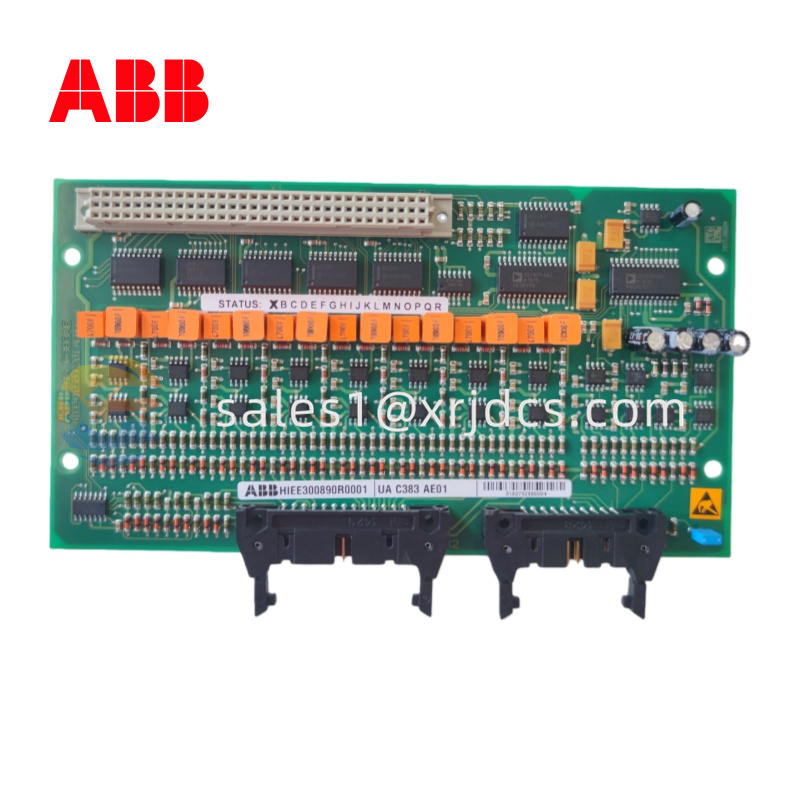

Structure and Composition

The ABB DSMB-01C module adopts the standard modular design of the S800 series. Its robust metal housing provides excellent electromagnetic shielding and heat dissipation performance. The front panel of the module is equipped with multiple groups of status indicator lights, including indicators for power status, operation status, fault status, and communication status. A high-speed fiber optic interface is configured at the front end for communication with the upper-level controller, ensuring the real-time performance and anti-interference ability of data transmission.

The internal structure of the module includes a high-performance Digital Signal Processor (DSP), a precise encoder signal processing circuit, a high-precision Digital-to-Analog Converter (DAC), and a comprehensive protection circuit. The DSP is responsible for running advanced control algorithms and real-time processing of position and speed commands; the encoder interface circuit processes feedback signals from the servo motor; the DAC generates precise ±10V analog control signals; the protection circuit monitors the system status in real time and provides protection functions such as overcurrent protection, overvoltage protection, and overspeed protection. The module is connected to the S800 base via a backplane connector to obtain working power and communicate with other I/O modules.

Key Features and Advantages

1. High-Precision Motion Control

The ABB DSMB-01C provides 24-bit high-resolution encoder processing and position control accuracy of ±1 pulse, enabling extremely precise motion positioning. Its high-speed control cycle (≤250μs) ensures fast dynamic response, meeting the strict requirements for motion control accuracy in high-end applications.

2. Powerful Real-Time Performance

The module uses a high-speed fiber optic interface to communicate with the controller, ensuring real-time transmission of motion control commands and feedback data, and has strong anti-electromagnetic interference capabilities. It supports seamless switching between multiple control modes, which can adapt to complex motion control requirements.

3. Comprehensive Diagnostic Protection

It is equipped with comprehensive online diagnostic functions, which can real-time monitor the servo system for conditions such as position deviation, speed abnormality, and overload. Multiple protection mechanisms are provided, including overcurrent protection, overspeed protection, and position over-tolerance protection, to ensure safe and reliable operation of the system.

4. Flexible Configuration and Maintenance

It supports flexible parameter configuration and optimization through ABB's engineering tools to adapt to different application requirements. The modular design facilitates installation and maintenance; the status indicator lights on the front panel provide intuitive system status display, which is convenient for quick fault diagnosis and troubleshooting.

Installation and Maintenance

Pre-Installation Preparation

Before installing the ABB DSMB-01C module, it is necessary to ensure that the system power supply is completely disconnected. Check that the S800 base is installed securely and confirm that the base model is compatible with the module. Prepare appropriate fiber optic cables and encoder cables, and ensure that the connector types match. Operators must wear anti-static wristbands to prevent electrostatic damage to electronic components. Confirm that the operating environment temperature, humidity, and vibration level meet the module's requirements.

Maintenance Recommendations

Regularly check the module's status indicator lights to confirm that the operation status is normal. Keep the module well-ventilated and regularly clean the dust on the heat sink. It is recommended to regularly check the connection status of fiber optic connectors and encoder wiring to ensure reliable connections. Use ABB's engineering tools to regularly check the servo system parameters and operating status for preventive maintenance. When the module needs to be replaced, it must be done after the system is powered off: first back up the parameter configuration, then loosen the fixing screws and pull out the old module smoothly. When installing the new module, ensure that the connector is fully inserted; after fixing it securely, restore the parameter configuration.

Xingruijia focuses on providing ABB industrial automation full range product services and your intelligent control solution partner

If you would like to learn more about our products and services, please feel free to contact us at any time!

Sales Manager : Jinny

Email : sales1@xrjdcs.com

Whatsapp/Mobile:+86 15359273791

Switzerland

Switzerland

.jpg)

.jpg)

.jpg)