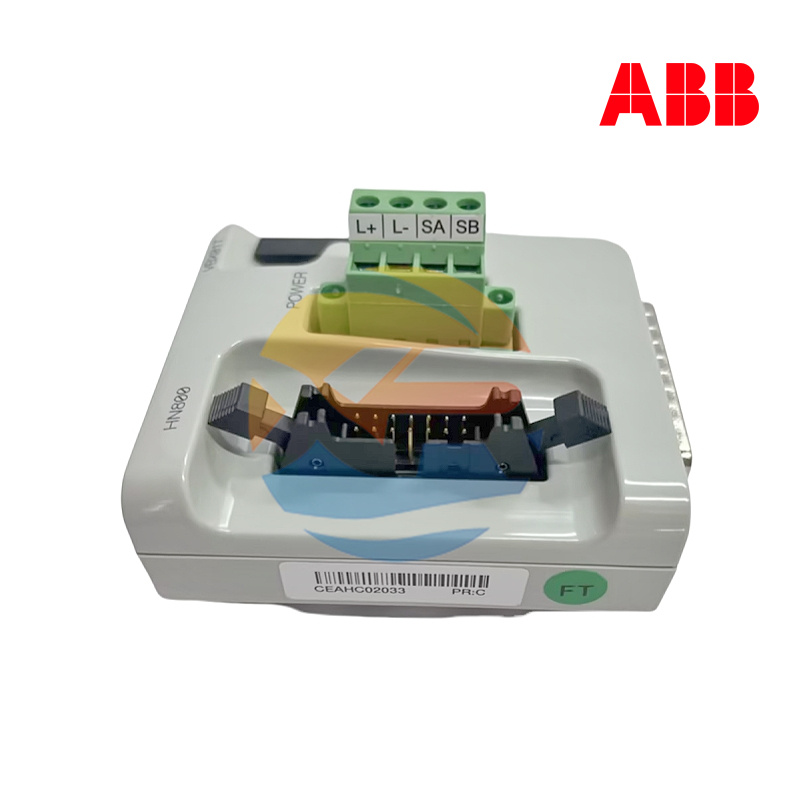

ABB VBX01TA

The ABB VBX01TA is a high-performance valve positioner launched by the Industrial Automation Division of ABB Group, and it belongs to the well-known TZIDC series of intelligent positioner family under ABB. In process control systems, this product acts as a key "precision executor", specifically designed for the accurate positioning and intelligent control of pneumatic control valves.

Adopting advanced non-contact magnetoelectric sensing technology and microprocessor control, the ABB VBX01TA can receive 4-20mA control signals from DCS (Distributed Control System) or PLC (Programmable Logic Controller) systems, and drive the actuator to reach the specified position with high precision. This positioner supports multiple characteristic curves (linear, equal percentage, quick opening, etc.) and is equipped with an automatic calibration function. It can adapt to different valve characteristics, providing excellent control accuracy and response speed. Its robust design and IP66/NEMA 4X protection class enable it to perform well in various harsh industrial environments, including process control applications in industries such as chemical engineering, petroleum, natural gas, and electric power.

Product Parameters

Product Model: VBX01TA

Manufacturer: ABB

Product Type: Intelligent Valve Positioner

Input Signal: 4-20mA (2-wire system), HART communication

Output Signal: Pneumatic output to actuator

Supply Pressure: 1.4-7.0 bar (20-100 psi)

Supply Connection: G1/4" female thread

Output Connection: G1/4" female thread

Stroke Range: Rotary stroke: 0-90°; Linear stroke: Configured according to the actuator

Accuracy: ≤±0.5% of span (including dead band)

Repeatability: ≤±0.1% of span

Sensitivity: ≤0.1% of span

Air Consumption: <0.03 Nm³/h (in steady state)

Operating Temperature: -40°C to +80°C (standard type)

Protection Class: IP66/NEMA 4X

Explosion-Proof Certification: ATEX, IECEx, FM, CSA

Mounting Method: Mounting on linear or rotary actuators

Material: Die-cast aluminum housing, stainless steel fasteners

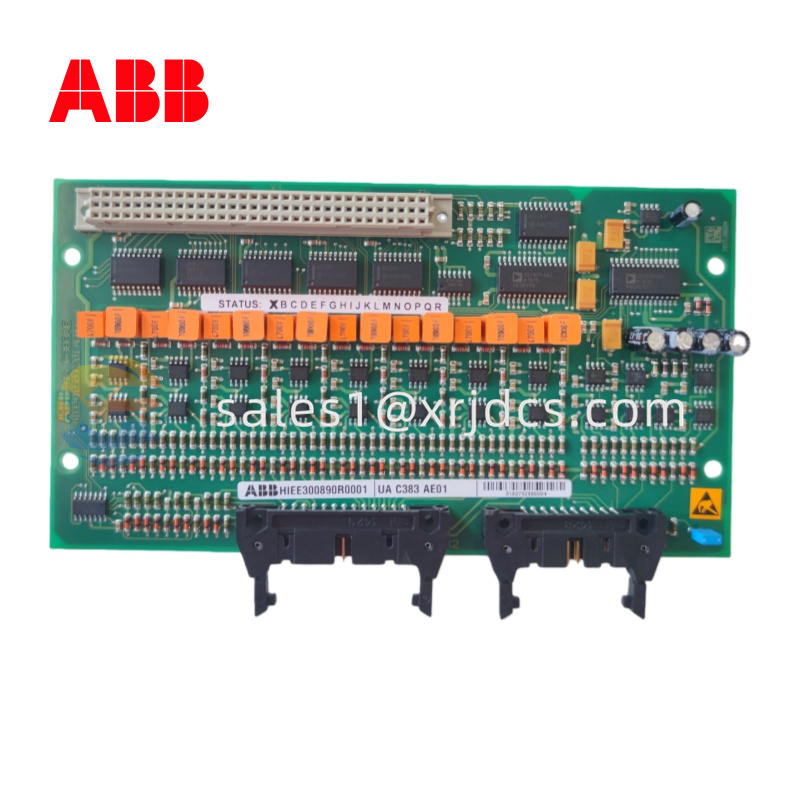

Structure and Composition

The ABB VBX01TA intelligent valve positioner features a robust die-cast aluminum housing, which provides excellent mechanical protection and electromagnetic shielding. The front of the device is equipped with a dual-line LCD display and three operation buttons for local setting and status display.

The internal structure includes several key components: high-precision Microprocessor Unit (MPU), non-contact magnetoelectric position sensor, piezoelectric valve group (PWM-driven), pneumatic amplifier, HART communication module, and power management unit. The position sensor detects the displacement of the valve stem or valve shaft in real time; the microprocessor compares the set value with the actual position and controls the piezoelectric valve group to output the corresponding pneumatic signal; the pneumatic amplifier provides sufficient air flow capacity to drive the actuator; the HART module enables two-way digital communication. The entire mechanism adopts a modular design, facilitating maintenance and component replacement.

Key Features and Advantages

High-Precision Control Performance: The ABB VBX01TA delivers high control accuracy of ≤±0.5% and repeatability of ≤±0.1%, ensuring precise control of valve position and significantly improving the quality of process control.

Advanced Auto-Calibration Function: Equipped with a one-button AutoCalibration function, it can automatically identify valve characteristics and optimize control parameters, greatly simplifying commissioning work and reducing commissioning time.

Powerful Diagnostic Capabilities: Built-in rich diagnostic functions can monitor parameters such as valve stroke, number of operations, and changes in friction coefficient, providing predictive maintenance information to help prevent unexpected shutdowns.

Excellent Environmental Adaptability: The IP66/NEMA 4X protection class and wide operating temperature range of -40°C to +80°C allow it to operate in the harshest industrial environments. Multiple explosion-proof certifications ensure safe use in hazardous areas.

Application Fields

The ABB VBX01TA intelligent valve positioner is widely used in industrial process fields that require precise flow control. In the petrochemical industry, it is used for reactor feed control and distillation tower temperature regulation; in natural gas processing, it is used for pressure regulation and flow control; in power plants, it is used for boiler feed water and steam temperature control; in water treatment systems, it is used for flow regulation and pressure control; in the paper industry, it is used for pulp concentration regulation; in the food and beverage industry, it is used for precise proportioning of process media. Any occasion that requires high-precision pneumatic valve control is an ideal application field for the VBX01TA.

Installation and Maintenance

Pre-Installation Preparation

Before installing the ABB VBX01TA, confirm that the actuator type (linear/rotary) and stroke range meet the requirements. Check the quality of the air supply to ensure clean and dry instrument air (the dew point should be at least 10°C lower than the minimum ambient temperature). Prepare appropriate mounting brackets and connectors.

Maintenance Recommendations

Regularly check the tightness of air supply joints to prevent leakage.

It is recommended to inspect the filter and pressure reducing valve every 6 months.

Regularly read diagnostic data through a HART handheld terminal or Valve Assistant software to monitor changes in valve performance.

Use neutral cleaning agents for cleaning, and avoid using corrosive chemicals.

Xingruijia focuses on providing ABB industrial automation full range product services and your intelligent control solution partner

If you would like to learn more about our products and services, please feel free to contact us at any time!

Sales Manager : Jinny

Email : sales1@xrjdcs.com

Whatsapp/Mobile:+86 15359273791

Switzerland

Switzerland

.jpg)

.jpg)

.jpg)