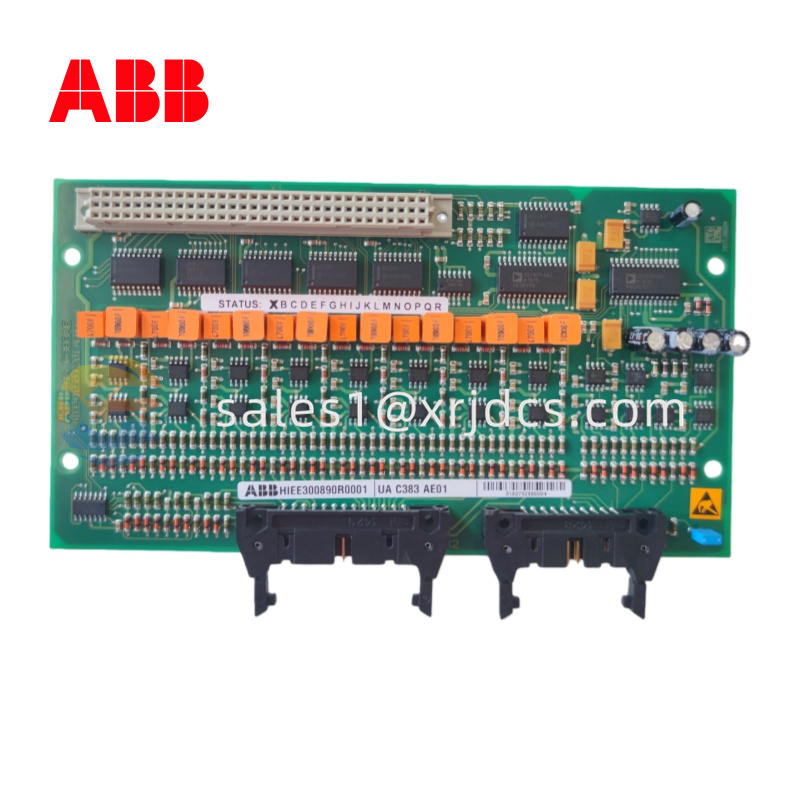

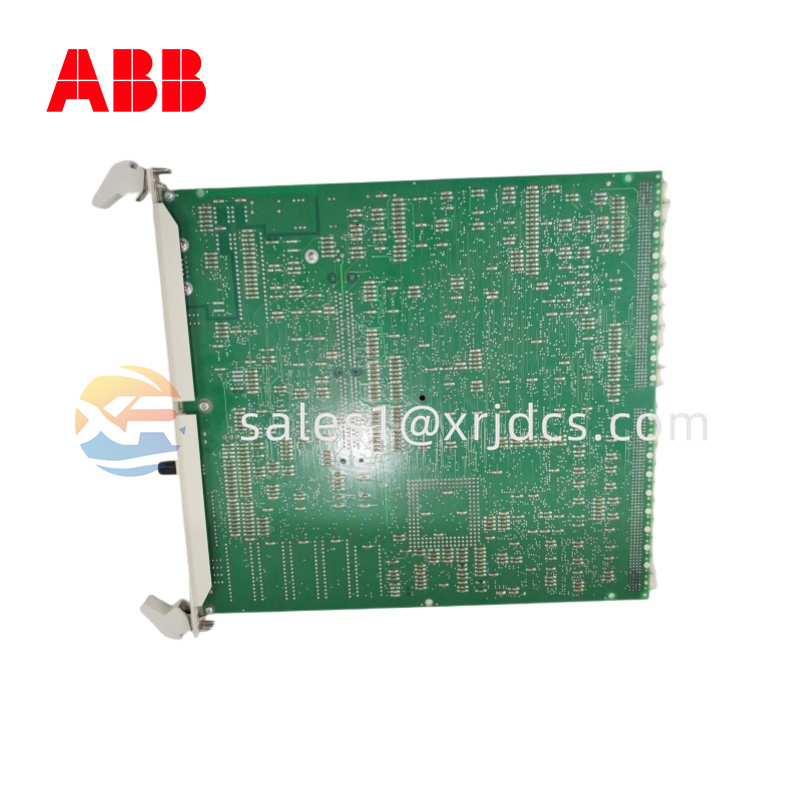

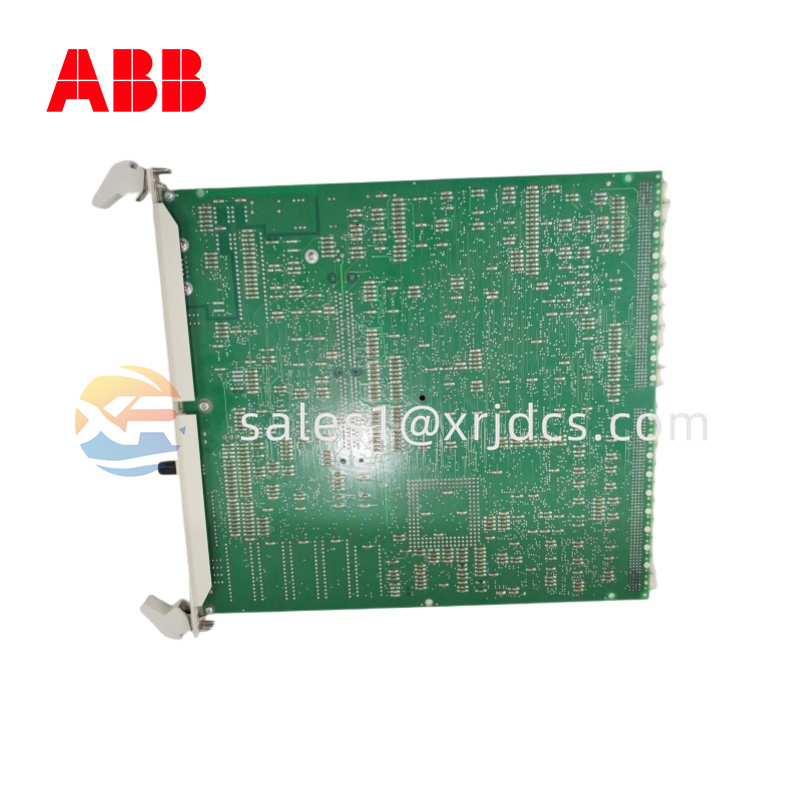

ABB PM510V16 3BSE008358R1 Processor Module

1. Key Features

The ABB PM510V16 3BSE008358R1 processor module is engineered for high-speed industrial automation control within ABB’s AC500 series PLC systems. Designed with advanced computational capability and robust reliability, it offers seamless data processing and communication for diverse industrial environments.

Main advantages include:

Powerful Processing Core: Handles complex logic, motion, and communication tasks simultaneously.

Multi-Protocol Support: Compatible with Ethernet, Modbus, and PROFIBUS interfaces.

Flexible Configuration: Scalable I/O expansion and easy programming with ABB’s Control Builder platform.

Enhanced Reliability: Built to operate in high-temperature, vibration, and EMC-sensitive environments.

Compact Design: Saves space while maintaining superior performance for both central and distributed control systems.

2. Overview

The PM510V16 module belongs to the ABB AC500 automation family, serving as a central processing unit (CPU) that coordinates I/O operations, data processing, and communication with external devices. It is widely adopted in process industries, energy management systems, and discrete manufacturing.

With ABB’s proven firmware and efficient architecture, the PM510V16 ensures deterministic response times and stable operation, making it ideal for mission-critical control applications.

3. Technical Specifications

Instead of a table, here’s a concise parameter overview for quick reading:

Manufacturer: ABB

Model Number: PM510V16

Part Code: 3BSE008358R1

Processor Type: 32-bit RISC CPU

Clock Frequency: Up to 16 MHz

Memory: 512 KB Flash, 128 KB RAM

Communication Ports: RS-485, Ethernet (TCP/IP), and optional fieldbus support

Power Supply: 24 V DC (tolerance ±10%)

Operating Temperature Range: –25°C to +70°C

Storage Temperature Range: –40°C to +85°C

Mounting Type: DIN rail mounting

Weight: Approx. 0.4 kg

4. Structure and Composition

Internally, the PM510V16 integrates a high-speed CPU board, memory modules, and multiple communication ports on a compact printed circuit assembly. The housing is made of industrial-grade thermoplastic for high insulation and resistance to vibration.

Front-facing LEDs provide clear diagnostic information such as power status, run/stop indication, and communication activity. Rear connectors allow secure attachment to I/O modules or power supply units, maintaining clean signal transmission and system stability.

5. Application Fields

The ABB PM510V16 module is an ideal solution for:

Factory automation systems — including packaging and material handling.

Water and wastewater treatment — for pump control and monitoring.

Power generation and energy distribution — SCADA and substation control.

Oil & gas processing — for distributed and redundant control architectures.

Building automation — for HVAC, lighting, and facility energy optimization.

Its modular nature makes it suitable for both standalone control and networked multi-PLC systems.

6. Installation and Maintenance

Installation: Mount on a standard DIN rail with proper grounding. Ensure the module is positioned in a ventilated area to avoid overheating.

Wiring: Connect according to ABB wiring guidelines, ensuring correct polarity of power supply and shielding of communication cables.

Maintenance: Requires minimal upkeep—regularly check connectors, clean dust from ventilation slots, and verify firmware updates using ABB Control Builder tools.

7. Additional Notes

The PM510V16 (3BSE008358R1) is fully compatible with other AC500 modules and I/O units, enabling easy scalability. Its low power consumption and high dependability make it a sustainable choice for long-term industrial use.

Switzerland

Switzerland

.jpg)

.jpg)

.jpg)