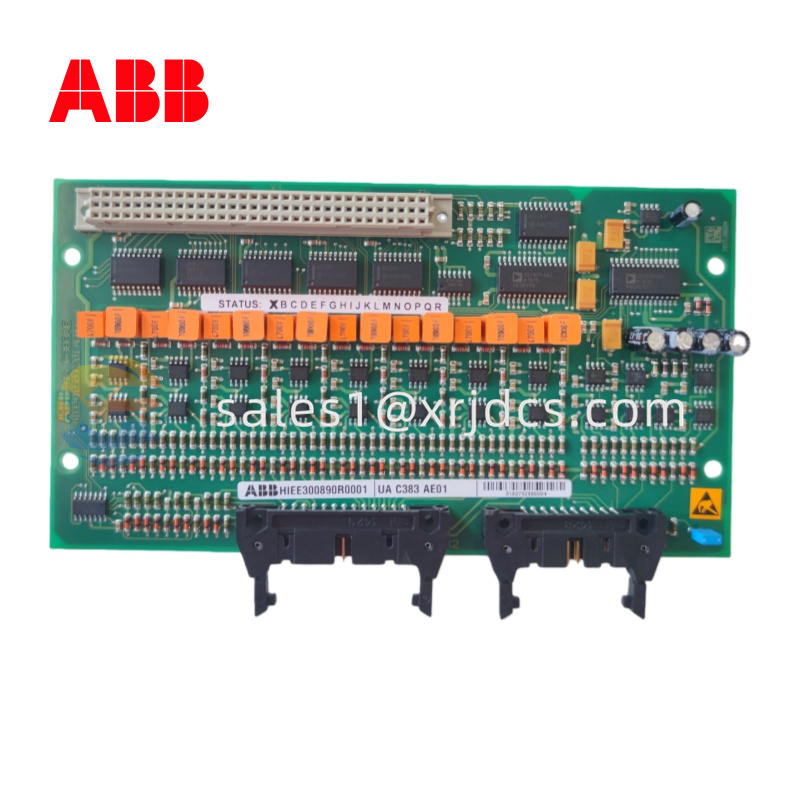

ABB CP800 – Intelligent Process Controller for Industrial Automation

Introduction

The ABB CP800 represents the next generation of intelligent process control solutions, combining high computing performance with reliable communication and flexible modularity. Designed for medium to large-scale automation systems, it provides the stability and scalability needed for continuous industrial operations.

Design & Structure

The CP800 features a compact modular housing that allows multiple expansion units to be connected without sacrificing performance. Its internal structure integrates:

A main processor module for real-time data processing.

I/O expansion interfaces for analog and digital signals.

Communication modules supporting various industrial networks such as Modbus, CANopen, and Ethernet/IP.

The robust aluminum casing ensures resistance to vibration, dust, and temperature variations, making it suitable for harsh factory environments.

Main Features

High Computational Power: Real-time data processing ensures precise and stable process control.

Multi-Protocol Communication: Compatible with a wide range of industrial networks.

Flexible I/O Configuration: Supports both centralized and distributed architectures.

Remote Access Capability: Enables monitoring, diagnostics, and updates through ABB’s engineering software tools.

Energy-Efficient Operation: Low power consumption with optimized heat dissipation design.

System Safety: Integrated watchdog timers and fault-tolerant mechanisms for uninterrupted performance.

Technical Data

Processor: 400 MHz ARM-based controller

Memory: 128 MB RAM, 64 MB Flash

Communication Interfaces: 2 × Ethernet ports, 2 × RS-485, 1 × USB

Power Supply: 24 V DC (range 18–30 V)

I/O Capacity: Up to 1024 I/O points (with expansion modules)

Operating Temperature: -25°C to +70°C

Storage Temperature: -40°C to +85°C

Installation Type: DIN rail mounting

Protection Level: IP20

Dimensions: 145 × 120 × 70 mm

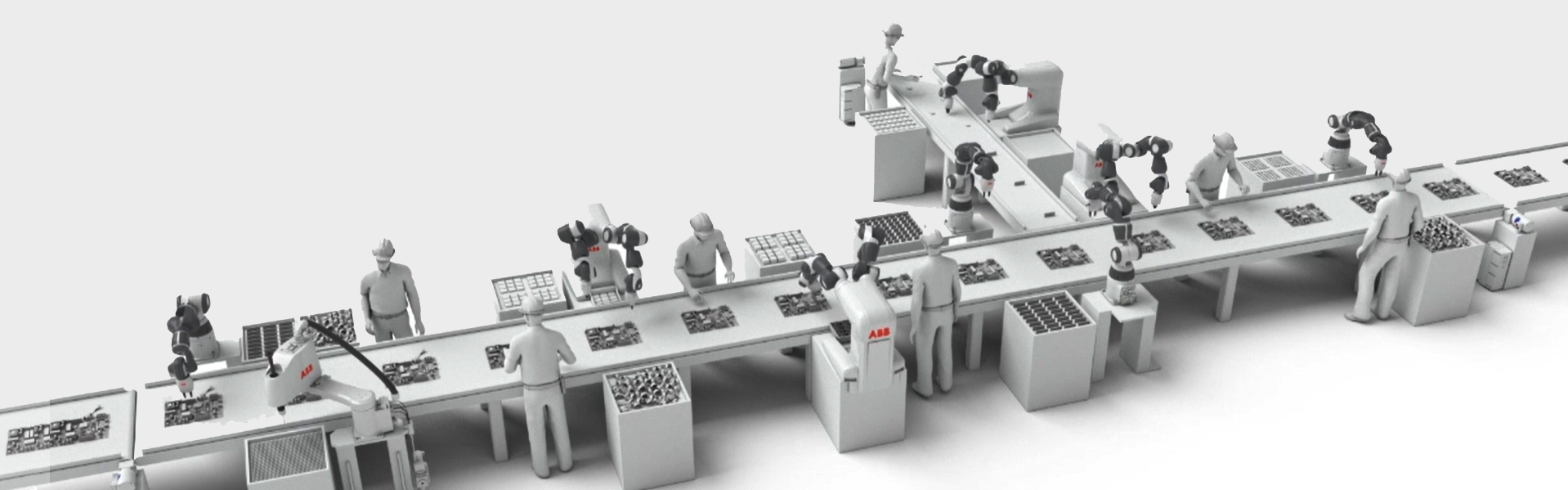

Applications

The ABB CP800 is extensively utilized in:

Chemical and Petrochemical Processing Plants

Power Generation and Distribution Systems

Water and Wastewater Automation

Food and Beverage Production Lines

Pharmaceutical and Biotech Manufacturing

Smart Building Management Systems

Its flexibility and compatibility with ABB’s automation ecosystem make it a preferred solution for both new installations and retrofit projects.

Installation & Maintenance Guidelines

Mounting: Secure the unit firmly on a standard DIN rail. Avoid excessive vibration or heat exposure.

Wiring: Follow ABB’s wiring diagram to connect I/O modules and communication lines.

Software Setup: Configure through ABB’s Control Builder software; assign control loops, I/O channels, and network parameters.

Maintenance: Perform routine inspection every six months—clean terminals, check grounding, and update firmware as necessary.

Benefits Summary

Simplifies integration in distributed control networks.

High reliability with low downtime.

Reduced engineering time with ABB’s preconfigured templates.

Long operational lifespan with minimal maintenance.

Switzerland

Switzerland

.jpg)

.jpg)

.jpg)